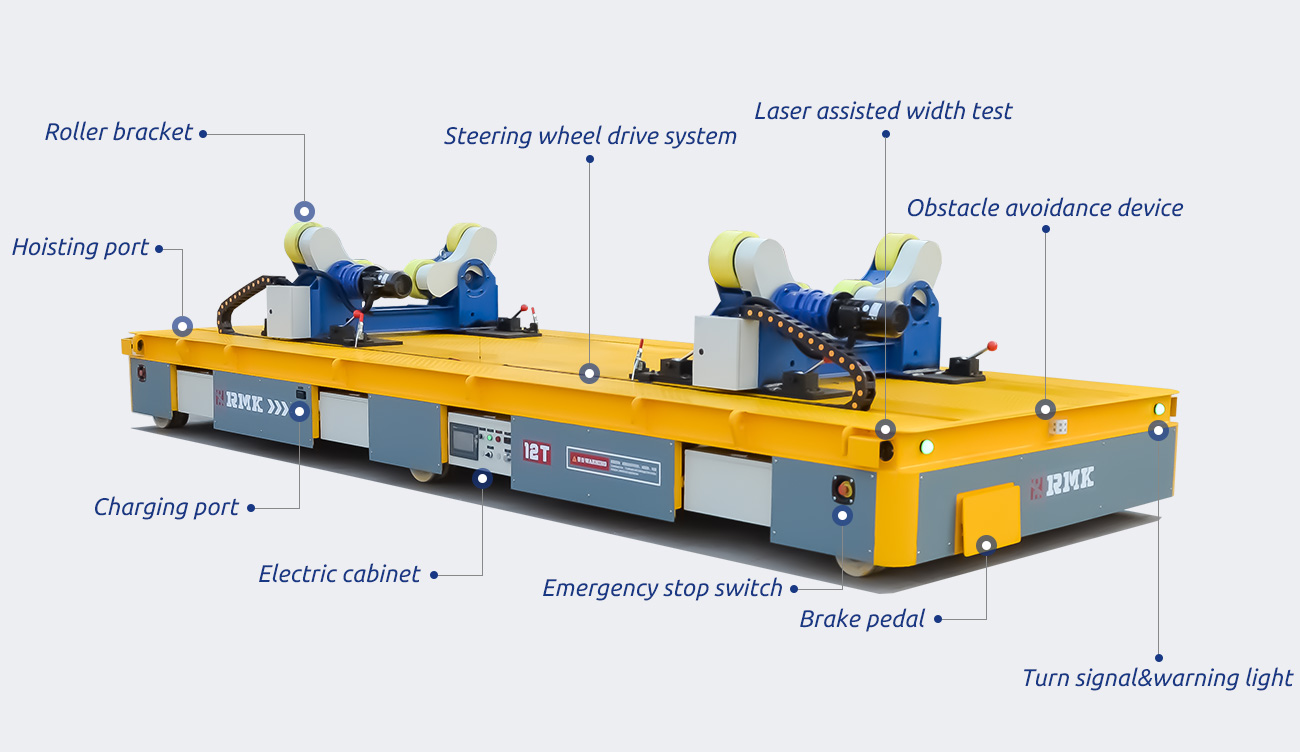

Remarkable steering wheel driven omnidirectional transport cart is composed of five major parts: car's steel frame, battery, steering wheel system, electrical system and safety detection. It can add a variety of application modes such as hydraulic lifting and roller system. The unique steering wheel system, which can move horizontally, obliquely, rotate 360 degrees in place,and move freely in narrow spaces. It is a very popular handling tool for modern industrial material transportation, and is used in various fields of modern industrial production. Remarkable provides 1 to 150 tons of non-standard customized solutions.

| Technical Parameters Table Of Omni-Directional Series Electric Trackless Transfer Cart | ||||||||||||||

| Rated Load Capacity (t) | 2 | 5 | 10 | 15 | 20 | 30 | 50 | 60 | 80 | 100 | 150 | 200 | ||

| Table Size(mm) | Length | 2000 | 2400 | 2700 | 3000 | 4000 | 4500 | 4500 | 5000 | 6000 | 6500 | 6500 | 6500 | |

| Width | 1300 | 1500 | 1800 | 2000 | 2000 | 2200 | 2200 | 2500 | 2500 | 2500 | 3000 | 3000 | ||

| Height | 450 | 500 | 550 | 700 | 700 | 700 | 650 | 700 | 700 | 700 | 750 | 750 | ||

| Ground Clearance (mm) | ≥50 | ≥100 | ||||||||||||

| Turning Radius (mm) | 0 | |||||||||||||

| Steering mode | Steering Wheel/Omni Wheel Steering | Differential Wheel Set Systems | ||||||||||||

| Operation Method | Remote Control & Hand Operate Pendant | |||||||||||||

| Move Way | Omnidirectional movement,Forward/backwards, rotation left/right, crab driving left/right,turning while driving with no stop,rotate 360° in place | |||||||||||||

| Running Speed (m/min) | 25 | 20 | ||||||||||||

| Motor Type | DC Servo Motor | |||||||||||||

| Brake Mode | Electromagnetic Brake | |||||||||||||

| Protective Measures | Audible and visual alarm lamp+ Emergency stop button+Laser obstacle avoidance sensor(Optional)+Anti-collision contact edge(Optional) | |||||||||||||

| Wheel Quantity | 4 | 8 | 12 | 16 | ||||||||||

| Suspension Type | Mechanical Automatic Regulation | Hydraulic Suspension | ||||||||||||

| Drive Wheel Diameter (mm) | Ф200 | Ф250 | Ф300 | Ф410 | Ф300 | Ф410 | Ф400 | Ф500 | Ф400 | Ф500 | Ф550 | Ф550 | ||

| Wheel Material | Steel Core + Polyurethane | |||||||||||||

| Battery Capacity (kW·h) | 4.8 | 7.2 | 10.5 | 12.5 | 14.4 | 15.1 | 22.5 | 30 | 37.8 | 45.3 | 60.5 | 75.6 | ||

| Battery Type | Lead-Acid Battery | Lithium Battery | ||||||||||||

| Battery Endurance | 5h Customized As Needed | 4h Customized As Needed | ||||||||||||

| Battery Charging Time | ≤7h | ≤5h | ||||||||||||

| Battery Charger | AC220V/AC380V | |||||||||||||

| Ground type | Cement Floor、Steel Plate Ground 、Epoxy Floor,Asphalt Floor | |||||||||||||

| Full-Load Climbing Capacity | 3% | |||||||||||||

| Working Environment | Temperature: -10°c~40°c; Humidity: 20%~80%, No Condensation (Customized for high-temperature and explosion-proof environments) | |||||||||||||

| Vehicle Body Color | Customized | |||||||||||||

| Other Functions | Battery Power Display,PLC,Visual Display Screen Designed On The Electric Control Cabinet ,Over Voltage, Under Voltage, Over Current Protection etc | |||||||||||||

| Versione Automatica – AGV | With navigation modes such as magnetic navigation, laser navigation, QR code navigation, and ribbon navigation, the AGV can achieve automatic handling functions. | |||||||||||||

| Notes: 1) Other table sizes and load capacities can be customized according to user requirements. 2) The number of wheel sets can be flexibly configured based on vehicle dimensions and load capacity. 3) This transporter series supports multiple navigation modes (magnetic, laser, QR code, or tape guidance) for AGV automated operation. 4) Battery type and operating time (battery endurance) can be customized to meet customer needs. 5) The product is subject to continuous improvement and upgrades; specifications in the table may change without prior notice. | ||||||||||||||

160 ton heavy load transporter omnidirectional mobile trackless transfer cart

160 ton heavy load transporter omnidirectional mobile trackless transfer cart

70 tons heavy-duty omnidirectional transport cart

70 tons heavy-duty omnidirectional transport cart

Multi-Drive battery transport cart with omni wheels

Multi-Drive battery transport cart with omni wheels

Heavy duty omnidirectional transfer cart with roller design

Heavy duty omnidirectional transfer cart with roller design

15 ton Steering wheel omnidirectional mobile trackless transfer cart

15 ton Steering wheel omnidirectional mobile trackless transfer cart

Multiway Battery Transport Cart

Multiway Battery Transport Cart

20 tons Industrial Material Handling Carts products pallets equipment

20 tons Industrial Material Handling Carts products pallets equipment

6 Tons Steering wheel Steel pipe trackless transfer cart

6 Tons Steering wheel Steel pipe trackless transfer cart

Self propelled electric transfer trolley

Self propelled electric transfer trolley

5 tons omnidirectional trackless transfer cart with hydraulic lifting

5 tons omnidirectional trackless transfer cart with hydraulic lifting

Heavy load battery powered mold transfer cart

Heavy load battery powered mold transfer cart

Battery powered multidirectional transfer cart

Battery powered multidirectional transfer cart

Electric multidirectional heavy duty transfer cart

Electric multidirectional heavy duty transfer cart

40 tons Omnimove transfer cart with dual platforms

40 tons Omnimove transfer cart with dual platforms

Battery Trackless Transfer Cart Omni Wheel With Scissor Lift

Battery Trackless Transfer Cart Omni Wheel With Scissor Lift

30 Ton Hydraulic Lifting Transfer Cart

30 Ton Hydraulic Lifting Transfer Cart

Omnidirectional Moving Trackless Transfer Cart

Omnidirectional Moving Trackless Transfer Cart

Steering wheel omnidirectional mobile trackless transfer cart

Steering wheel omnidirectional mobile trackless transfer cart

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.