RGV automated rail transfer trolley, with high speed, high reliability, low cost and other characteristics, is mainly used for industrial materials transport and workshop assembly and widely used in automated workshops. Remarkable provides various customized RGV automated rail transfer trolleys,such as the ferry rail transfer trolley, the vertical and horizontal moving automated rail transfer trolley, etc.

| Technical Parameters Table Of KPD Low Voltage Electric Rail Transfer Cart | |||||||||||||

| Rated Load Capacity (t) | 5 | 10 | 15 | 20 | 30 | 40 | 50 | 60 | 80 | 100 | 150 | 200 | |

| Table Size(mm) | Length | 2000 | 2400 | 3000 | 3000 | 4000 | 4500 | 5000 | 5000 | 6000 | 6000 | 7000 | 8000 |

| Width | 1300 | 1500 | 2000 | 2000 | 2200 | 2200 | 2500 | 2500 | 2500 | 2500 | 3000 | 3000 | |

| Height | 450 | 500 | 550 | 550 | 600 | 600 | 700 | 700 | 800 | 800 | 900 | 900 | |

| Ground Clearance (mm) | ≥50 | ||||||||||||

| Wheelbase (mm) | 1300 | 1600 | 2000 | 2000 | 2700 | 3000 | 3300 | 3300 | 4000 | 4000 | 4800 | 5500 | |

| Rail Inner Distance (mm) | 900 | 1100 | 1435 | 1435 | 1435 | 1435 | 1650 | 1650 | 1650 | 1650 | 2000 | 2000 | |

| Operation Method | Remote Control & Hand Operate Pendant | ||||||||||||

| Move Way | Forward/backwards, Turning (Customized), Vertical-Horizontal Crisscross Movement (Customized) | ||||||||||||

| Running Speed (m/min) | 25 | 20 | |||||||||||

| Motor Type | Three-Phase Asynchronous Motor | ||||||||||||

| Brake Mode | Electromagnetic Brake | ||||||||||||

| Protective Measures | Audible and visual alarm lamp+ Emergency stop button+Limit switch+Laser obstacle avoidance sensor(Optional)+Anti-collision contact edge(Optional) | ||||||||||||

| Wheel Quantity | 4 | 8 | |||||||||||

| Wheel Material | ZG55 | ||||||||||||

| Drive Wheel Diameter (mm) | Ф300 | Ф300 | Ф350 | Ф350 | Ф400 | Ф400 | Ф500 | Ф500 | Ф600 | Ф600 Heavy Duty Wheel | Ф700 Heavy Duty Wheel | Ф600 Heavy Duty Wheel | |

| Recommended Rail Type | P15 | P18 | P24 | P24 | P38 | P38 | P43 | P43 | QU70 | QU70 | QU100 | QU100 | |

| Power Supply Mode | Step Down 380V To 36V, And Step Up 36V To 220V | Step Down 380V To 36V And Step Up 36V To 380V | |||||||||||

| Rail Quantity | 2 | 2+1 Conductive Rails | |||||||||||

| Transformer Power (kVA) | 3 | 3 | 6 | 6 | 6 | 10 | 10 | 10 | 10 | 20 | 20 | 30 | |

| Working Environment | Temperature: -10°c~40°c; Humidity: 20%~80%, No Condensation(Customized for high-temperature and explosion-proof environments) | ||||||||||||

| Vehicle Body Color | Customized | ||||||||||||

| Other Functions | Over Voltage, Under Voltage, Over Current Protection etc | ||||||||||||

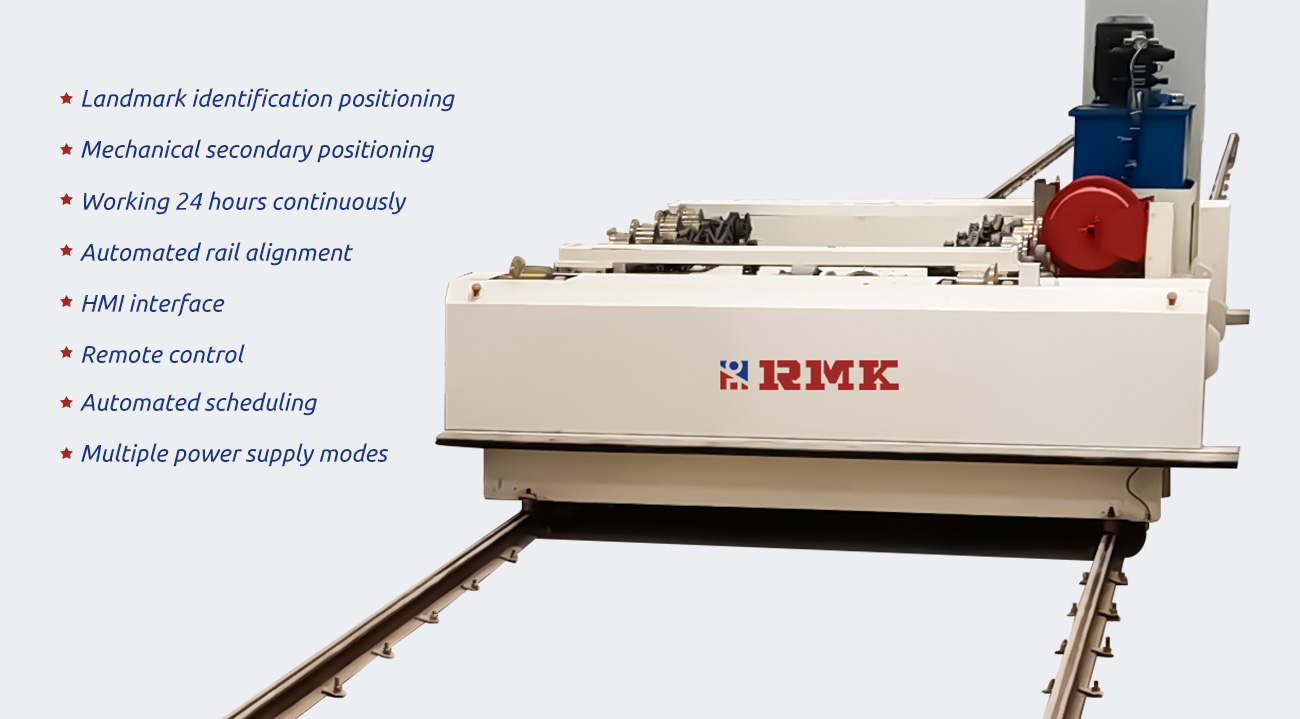

| Versione Automatica – RGV | Combined With An Automatic Positioning System, Signal Reception System, And Programmable System, The Rgv Realizes Automated Handling Functions. Customizable Rgv Carts Such As Mother-Child Carts (Ferry Carts), Vertical-Horizontal Moving Carts, And Curved Track Carts Can Be Provided. | ||||||||||||

| Notes: 1)Other gauges, table sizes, and load tonnages can be customized according to user requirements. 2)This model of rail trolleys can be customized with special vehicles such as mother-child cars, curved track carts, vertical-horizontal moving carts, etc., to meet specific usage needs. 3)This model of rail trolleys can receive instructions from call boxes and host computers to achieve automated handling. 4)The rail>50m, the number of step-down transformers needs to be appropriately increased to compensate for the voltage drop in the rail. 5) The product is subject to continuous improvement and upgrades; specifications in the table may change without prior notice. | |||||||||||||

50 Ton Rail Electric Traction Trolley

50 Ton Rail Electric Traction Trolley

15 ton explosion-proof electric rail transport cart apply aerospace equipment

15 ton explosion-proof electric rail transport cart apply aerospace equipment

Coil transport cart applied in the field of new energy

Coil transport cart applied in the field of new energy

Steel industry rail transfer trolley

Steel industry rail transfer trolley

Coil transfer cart Automated electric rail transfer trolley

Coil transfer cart Automated electric rail transfer trolley

35 tons lifting automated rail transfer trolley

35 tons lifting automated rail transfer trolley

12 tons battery steel billet automatic rail transfer cart

12 tons battery steel billet automatic rail transfer cart

Casting Industry Rail Tractor RGV trolley

Casting Industry Rail Tractor RGV trolley

RGV Automated Rail Transport Platform

RGV Automated Rail Transport Platform

RGV automatic rail transfer cart for machinery manufacturing

RGV automatic rail transfer cart for machinery manufacturing

2 tons RGV Automated Rail Transport Platform

2 tons RGV Automated Rail Transport Platform

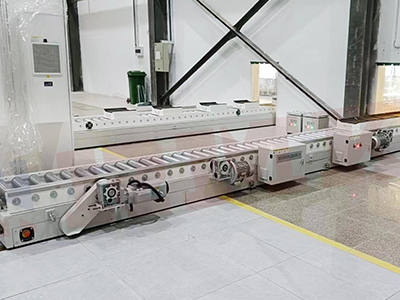

warehouses industrial Automated rail transfer trolley

warehouses industrial Automated rail transfer trolley

30 Tons Rail guide vehicle electric transfer cart coli transport car

30 Tons Rail guide vehicle electric transfer cart coli transport car

Model Transportation Tool material handling between factories

Model Transportation Tool material handling between factories

Forklift Arm-type Automated Rail transfer cart RGV

Forklift Arm-type Automated Rail transfer cart RGV

Railway shunting hook removal robot-Automated rail transfer cart

Railway shunting hook removal robot-Automated rail transfer cart

Coil Automated Rail Transfer Cart

Coil Automated Rail Transfer Cart

40 Tons+40 Tons Dual Cart Linkage Automated RGV

40 Tons+40 Tons Dual Cart Linkage Automated RGV

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.