The double hydraulic steering 40 Tons Heavy Duty Battery Transporter designed by Henan Remarkable for customer in Türkiye has many highlights in technical design and functional configuration:

Core Performance and Design Highlights

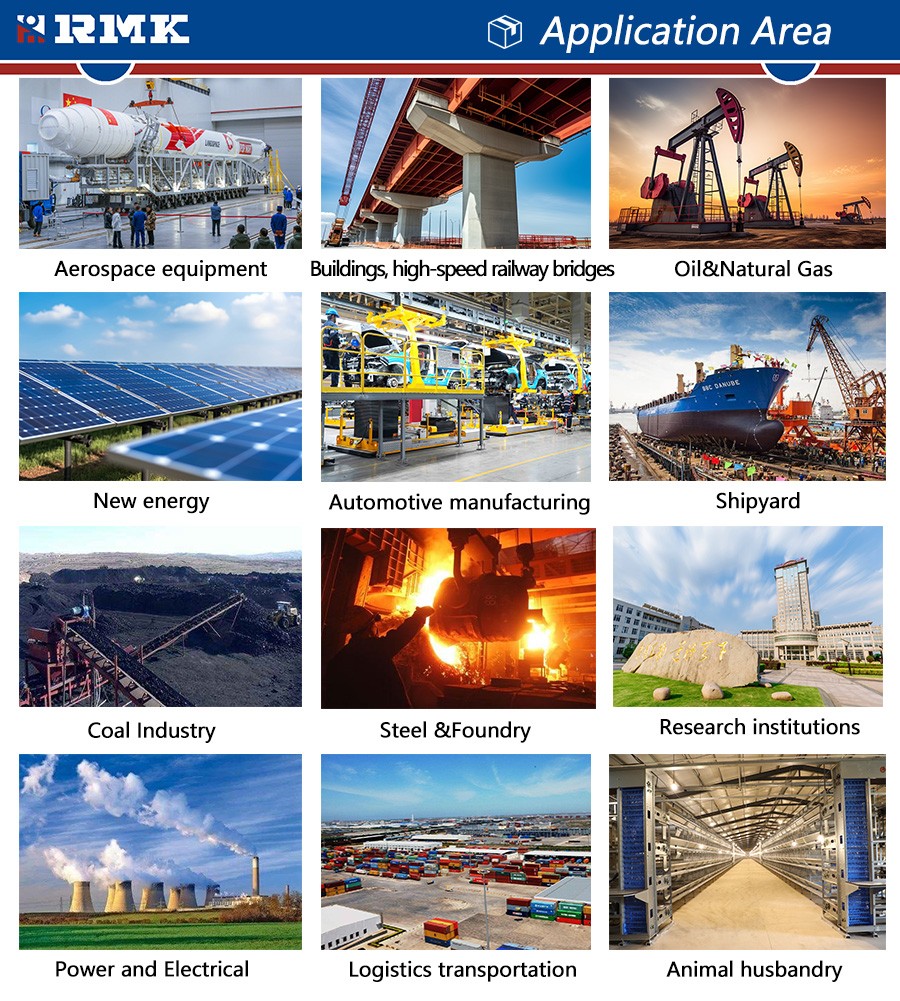

-Large load capacity and customized countertop: Suitable for heavy goods such as steel structures, steel plates, transformers, etc. with a load capacity of 40 tons. The countertop size is customized according to customer needs, taking into account both large load capacity and on-site operation space.

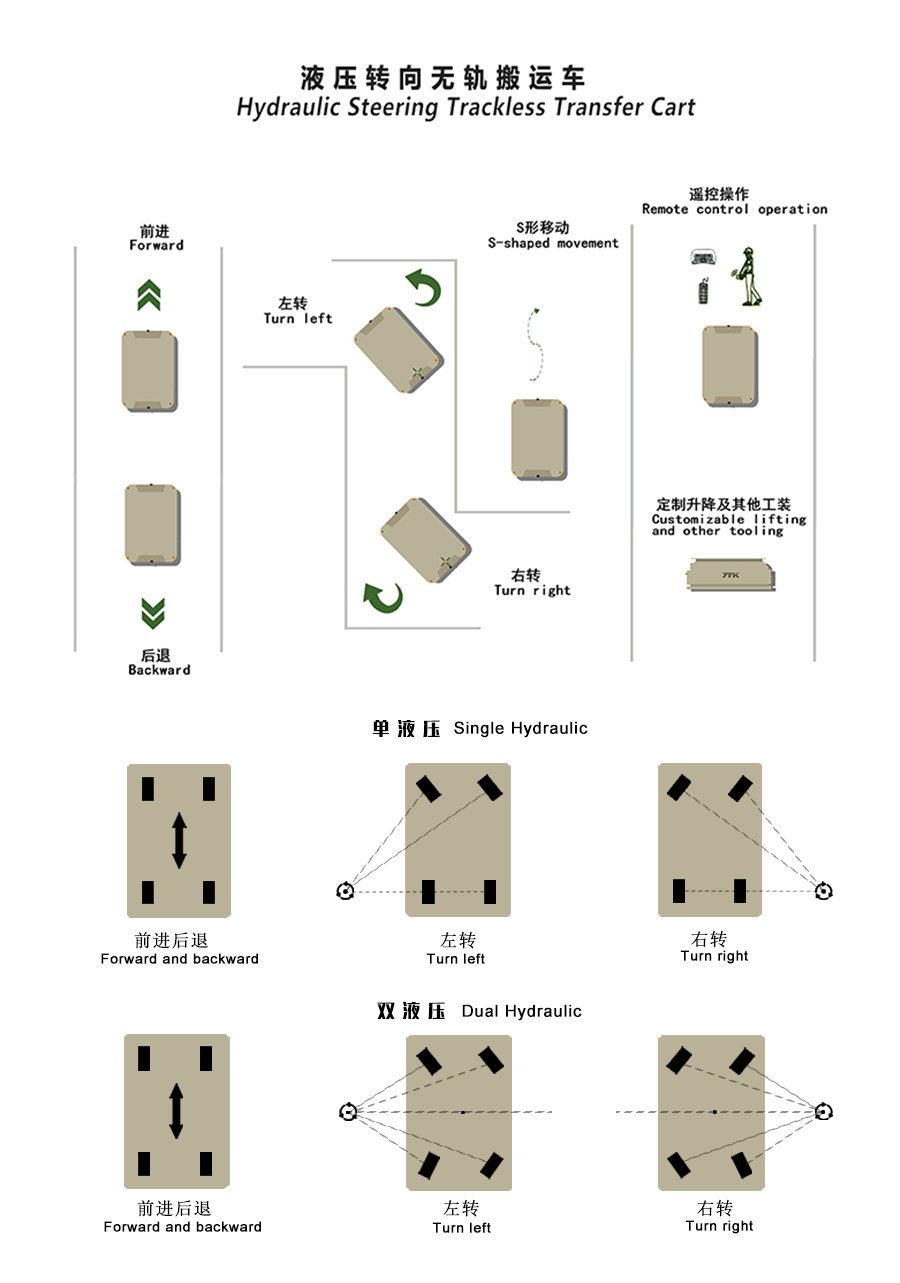

-Dual hydraulic steering mechanism: Controlled by a hydraulic system, it can better balance the turning flexibility and smoothness of large platform equipment compared to traditional differential steering. Especially in narrow areas, it can achieve more precise steering operations and avoid turning difficulties caused by large platforms.

-Multiple safety protections: equipped with emergency stop button, sound and light alarm, and laser obstacle avoidance system, which can provide real-time warning of obstacles and emergency braking during transportation, improving the safety of complex site operations.

Application scenario adaptability

This model is designed for the transportation needs of large goods such as steel structures and pressure tanks. Dual hydraulic steering can reduce the body shaking during heavy load turning, while laser obstacle avoidance is suitable for scenarios such as factories and warehouses where personnel or equipment may cross. It not only meets customers' requirements for transportation efficiency, but also takes into account safety regulations.

Main technical parameters about the 40 tons die transport platform:

Load capacity: 40 tons

Table size: 11*3*0.95m

Power supply mode: lead acid battery 72V 400Ah

Speed: 0-25m/min

Protective devices: alarm light, emergency stop button, laser scanning sensor

Painting color: Yellow+ gray

Operate mode: wireless remote control+hand pendant

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.