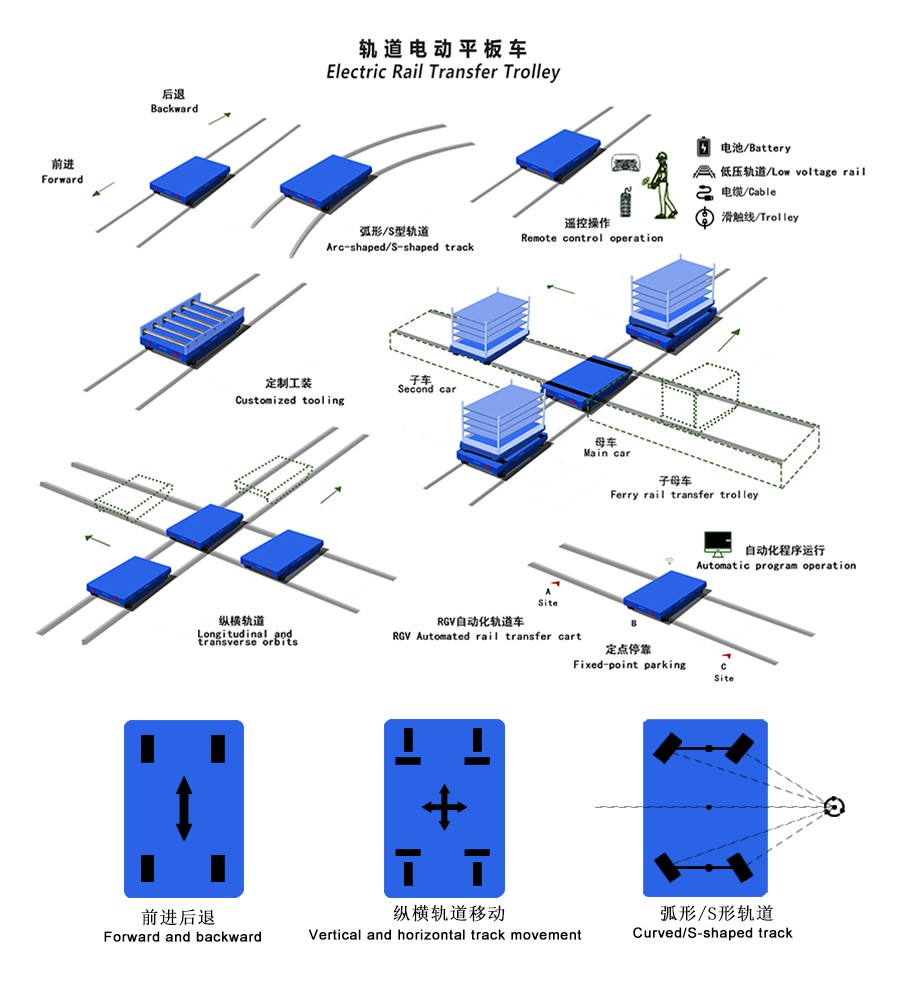

Coil rail transfer cart is used for transporting various types of coils, such as steel coils, aluminum coils, iron coils, paper rolls, and other metal, paper, plastic, and other types of coils. It runs smoothly and can be customized according to demand for load capacity. It is suitable for industrial workshops with relatively fixed transportation paths and high production frequency and efficiency. Rail transfer carts can be designed in linear, circular, curved, and cross longitudinal and transverse mobility. The key is that the rail transfer cart can achieve different levels of intelligence and automation according to demand, and the Remarkable automated rail transfer cart, also known as RGV, can be used. We have many successful experiences and cases of automated rail transportation in the online circle, and are constantly innovating technology to provide customers with a complete set of solutions.

Remarkable has provided a complete set of automated rail transfer cart transportation solutions for Jingbo Group's new workshops in different regions such as Hangzhou and Luoyang. This group is a well-known enterprise that produces new energy and batteries. An important link in their production is the transportation of aluminum coils, which need to be transported to different workstations according to the planned route. The work pace is very fast and high, and the work frequency and efficiency are also required to be very high. For this purpose, we have designed a vertically and horizontally mobile automated rail transfer cart for our clients, which is powered by batteries, automatically charged, and has multiple positioning methods. Multiple vehicles work simultaneously, participate in work mobilization, and cooperate with third-party devices through interconnection. The aluminum coil that the customer wants to transport is handled and loaded/unloaded using a scroll. We have designed a lifting small V-shaped frame for the customer, which effectively reduces the height of the vehicle body. It has achieved unmanned and efficient automation, which is very suitable for customers' production rhythm and production capacity improvement.

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.