This Heavy Load 10 Tons Mold Lifting Transfer Cart Is Designed For Polish Customer. This Heavy-Duty Transfer Trolley Has Hydraulic Steering To Ensure Smoother And Safer Transportation Of Goods. Due To The Customer's Requirement For A Lower Platform, We Have Designed The Scissor Lift Platform In The Middle Of The Platform, With A Total Lifting Stroke Of 800mm With The Efforts Of Our Professional Technical Team, We Have Met The Usage Needs Of Our Customers. This Platform Transfer Vehicle Can Move Forward, Backward, Left Turn, Right Turn, And Turn While Walking. There Are Also Emergency Stop Buttons, Warning Lights, Etc. Installed To Ensure That In Case Of An Emergency, The Emergency Stop Button Can Be Pressed To Quickly Stop The Cart.

Main Technical Parameters About Battery Powered Trackless Transfer Carts:

Model:RWP-10T

Table Size(Mm):4000*2000 *500

Lifting Stroke(Mm):800

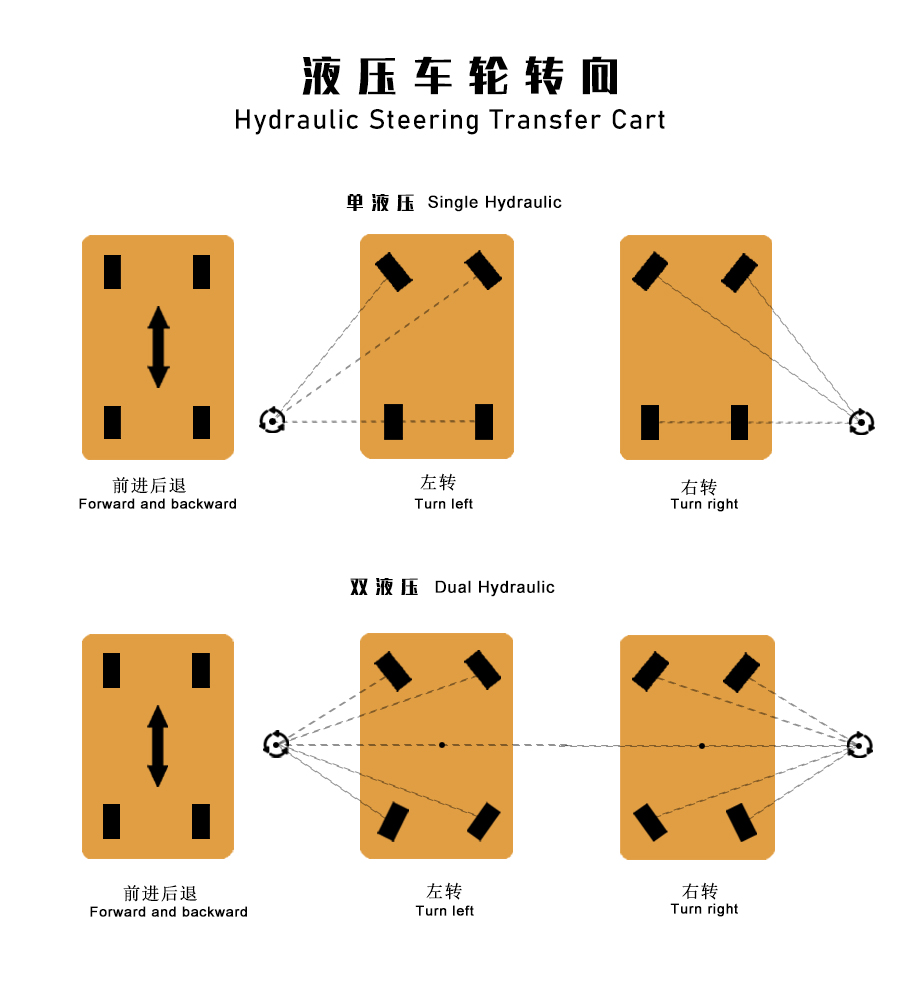

Move Way:Forward/Backwards, Rotation Left/Right, Left/Right, Turning While Driving With No Stop

Wheel Material:Polyurethane Rubber Coated Wheel

Wheel Quantity:4

Power Supply Mode: Maintenance-Free Lead-Acid Battery

Operate Mode: Remote Control+Hand Pendant

Turning Mode: Hydraulic Turning

The battery powered transfer carts has the following functions:

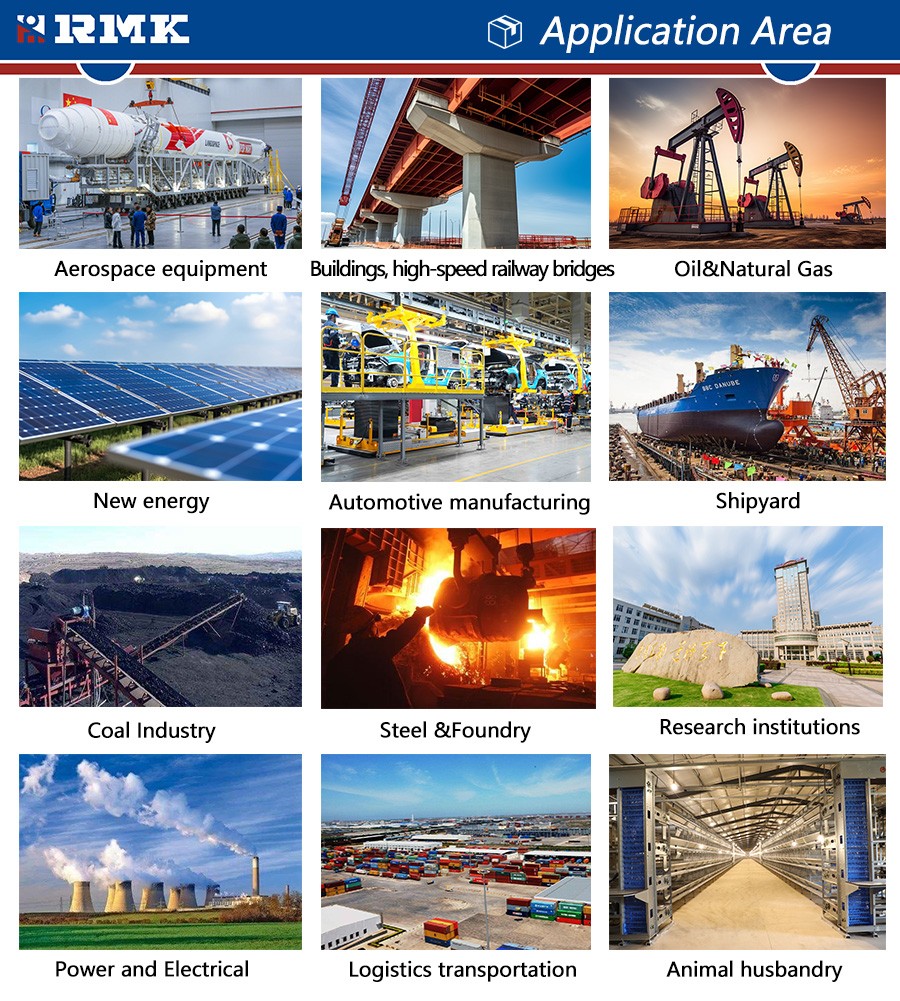

-Transportation function: As the main function, the battery transfer trolleys can carry goods or personnel of different weights and perform transportation operations in various locations, such as handling raw materials and components in factories, transferring goods in warehouses, and transporting goods or personnel in hospitals, airports, and other places

-Steering function: Through a special steering system and wheel design, flexible steering such as 360 degrees rotation in place and small radius turning can be achieved. The driving direction can be freely adjusted in narrow spaces, improving work efficiency and site adaptability

-Lifting and auxiliary functions: Some trackless transport platforms can be equipped with hydraulic, mechanical and other lifting devices according to their needs to achieve the lifting and lowering of goods. Auxiliary devices such as clamping devices, positioning devices, and tabletop rolling devices can also be installed.

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.