This Heavy Load 20 Tons Transformer Battery Transfer Cart is composed of a motor, wheels, reducer, electric control box, battery pack, box girder structure frame, remote control and hand pendant, etc. It is designed with a differential steering mechanism, which is flexible in steering and runs smoothly. In order to protect the goods, we have specially designed fumigated solid wood panels on the table according to the customer's needs. This not only protects the goods, but also has a protective effect on the platform of the transfer trolley.

Main technical specifications about the transporter:

Load capacity: 20 tons, it can be customized according to customer's requirements and needs

Table size: 3*2*0.7m

Power supply mode: Maintenance-free lead-acid batteries

Speed: 0-20m/min

Operate mode: remote control+hand pendant

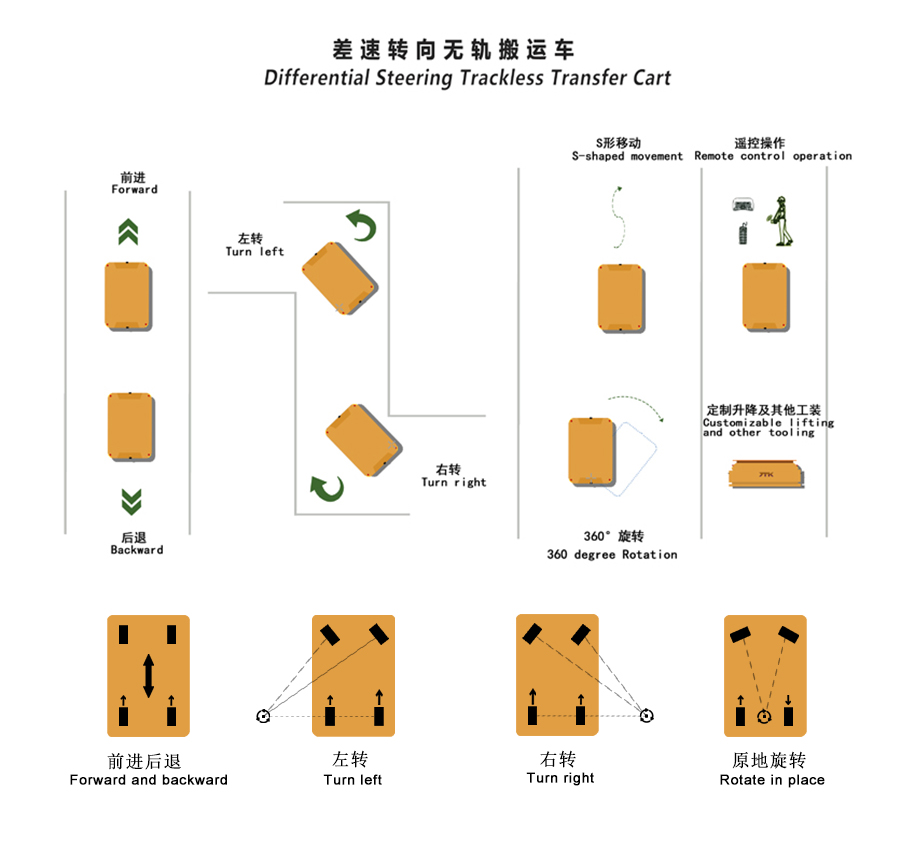

Move way: forward, backward, rotate 360 degrees, turning while in moving without any stop

This battery powered transformer transfer trolley is mainly composed of differential steering as the steering mechanism, polyurethane coated wheels, maintenance free lead-acid batteries, low-voltage AC motors, reducers, electric control boxes, remote controllers, and on-board handles.

Characteristics about trackless transfer cart:

-High flexibility of heavy duty transport platform: not limited by tracks, able to freely travel and turn on flat ground, can quickly reach different work areas, suitable for various complex and changing work environments and temporary work needs.

-Environmental protection and energy conservation for heavy load transporter: Powered by batteries, with no exhaust emissions, low noise during operation, environmentally friendly, and relatively low electricity costs, it can reduce operating costs and meet environmental protection and energy conservation requirements.

-Low maintenance cost: The structure is relatively simple, with fewer components and no need for complex track maintenance, reducing maintenance workload and costs.

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.