Expertise On The Market Of Rail Transfer Carts, Including Shuttle Lifting Cars, Made Our Company A Leader In A Variety Of Sectors On Both Local And International Markets Offering Solutions Designed With Special Treatment And Tailored According To Customer’s Needs. Used In Industrial Plants, Building Sites, Offshore Platforms And Vessels, Our Rail Guided Powered Trolleys Feature A Complete Set Of Power Supply: Diesel, Battery, Electric Grid And Pneumatic Versions.

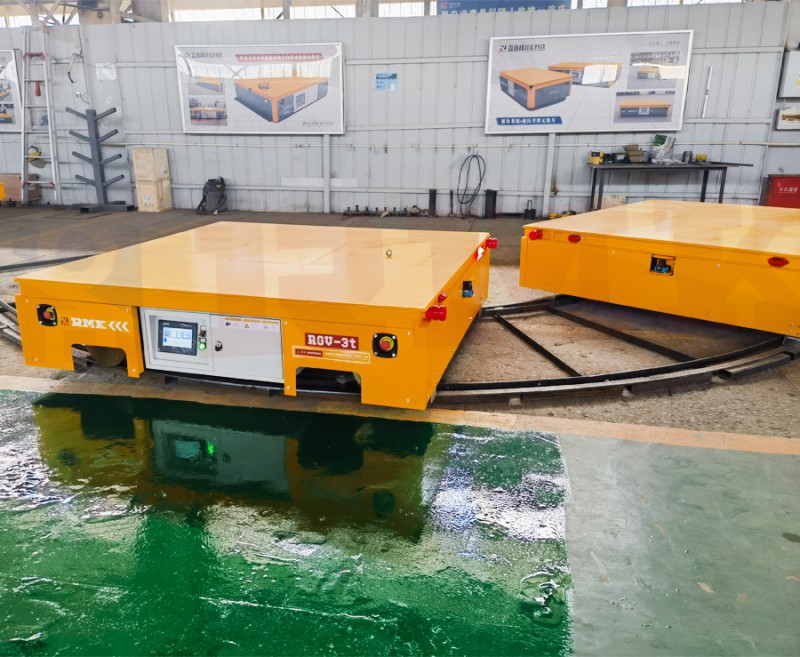

RMK Rail Transfer Cart Models Will Perfectly Suit Your Needs For Coil Handling In Steel Industry, Concrete Manufacturing, Transportation In Factories, Warehouses, Ports And The Variety Of Hard Duty Fields Where Moving On Rails Is Required And Production Cycles Are Regular Both Time-Wise And Route-Wise. RMK Offers Modern Die Change Carts On Rails To Respond To Rapid Changes In Metalworking Industry And Reshape Its Logistics.

As They Are Equipped With Steel Wheels And Move On Steel Rails They Are Suited To Very High Loading Capacities Thanks To The Very Low Friction Between Steel And Steel. For This Reason Listed Above, The Cost Of These Transfer Trolleys – Referring To Same Dimensions And Loading Capacity – Is Lower Than Battery And Diesel Powered Trolleys On Wheels Which Must Be Equipped With Steering Systems And Greater Power.

We Produces A Wide Range Of Automatic Rail Transfer Cars, Coil Transfer Cars And Shuttle Lifting Cars, That Final Customers And EPCs Use To Automatize A Specific Handling Process. RMK Can Supply Even Whole Automatic Transfer Carts, That Can Dialogue With The Customer’s Plant Management Software.

Technical Parameter

load capacity:80T

Table size:6000*2500mm

power supply:battery

working time:3H

Wheel type:Polyurethane wheels

Traveling speed:0-20m/m

operating mode:Wireless remote control & Hand operate pendant

Climbing slope:No more than2 degrees

Brake mode:Electromagnetic brake

Safety device:Audible and visual alarm lamp and emergency stop button

Charger install type:Split-type

Mode of Turning :Electric button control

Other functions:Equip with battery display

Move Way:Forward,backward ,turning while driving with no stop

Flat car’s protection:Overvoltage, undervoltage, overcurrent protection etc

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.